OUR SERVICES

WHAT WE DO

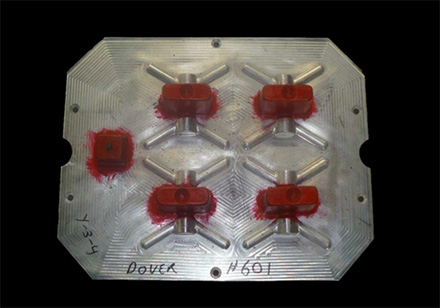

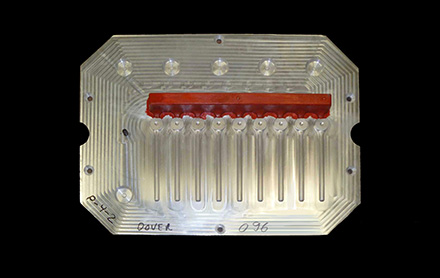

Sand Casting Process: Below is an example of match plate sand casting, one of several processes used to produce the Dover product line. Additionally, we use investment casting, forging, welding, and machining.

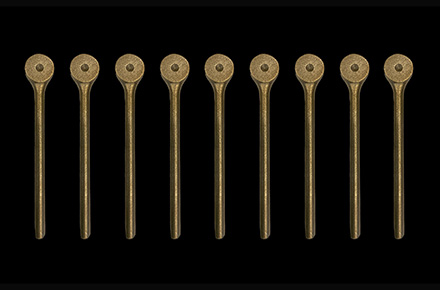

3/8” X 6” Dog Bolt

3/8” X 6” Dog Bolt

Machining

3/8” X 6” Dog Bolt